Money doesn’t grow on trees, but the diesel that powers your vehicle could soon be made out of nothing but thin air.

It might sound like an idea plucked straight from the pages of a sci-fi novel, but small companies have already started doing exactly this, sucking carbon dioxide from the air and transforming it into fuel known as ‘e-diesel’.

The science behind it actually dates back to the 1920s, when German scientists Franz Fischer and Hans Tropsch created the Fischer-Tropsch process, which can turn CO2 into useable fuel.

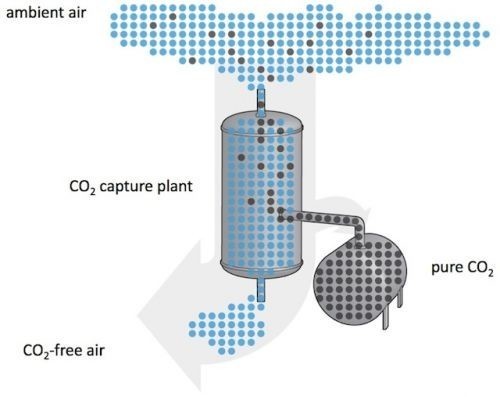

Splitting water into hydrogen and oxygen via electrolysis, it’s then just a relatively simple process of adding the extra hydrogen generated to carbon dioxide, piling on more and more to build up the hydrocarbon chains that form diesel.

Though it’s been around for 90 years, it’s only now that the technology used to snare the CO2 from the air is being cheap and common enough to be viable.

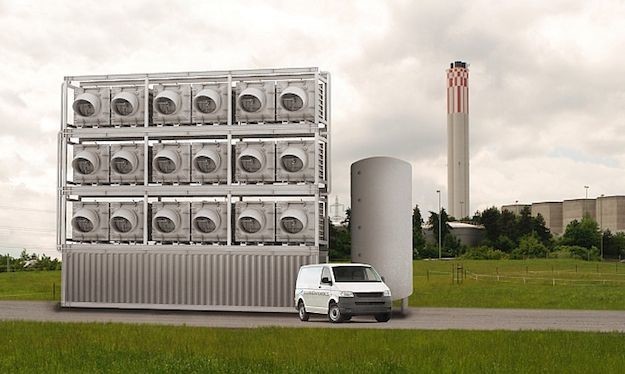

Enter German company Sunfire and Canadian engineers Carbon Engineering, two pioneers in the nascent e-diesel industry. Back in April, Sunfire produced its first batches of e-diesel and presented them to German Federal Minister of Education and Research Johanna Wanka, who even put a few litres in her car to celebrate.

Likewise, Carbon Engineering just recently announced that it’s built a new plant which it claims can scoop as much as two tonnes of carbon dioxide from the surrounding air every day, enough for 500 litres of diesel.

Though the process requires electricity, the hope is that the companies can use renewable electricity to produce diesel that’s completely carbon neutral. Burning e-diesel in your car returns it to the atmosphere, where it’s scooped back into the machines and made into more diesel.

Not only does this present a genuinely viable alternative to crude oil-derived fuels, it could also be used to actively combat pollution and greenhouse gases in the atmosphere, reducing the threat of climate change.

CO2 concentrations in the air reached an average of 400 parts per million between 2012 and 2013, the highest recorded amount since scientific measurements began. Furthermore, the year between July 2014 and June this year was the warmest on record, according to the US National Oceanic and Atmospheric Administration.

One of the key breakthroughs in the technology came from Carbon Engineering, which developed a process to precipitate captured CO2 into solid calcium carbonate pellets, which release pure CO2 when heated.

After the carbon dioxide has been burned off, the pellets leave calcium oxide as the only residue, which can then be fed back into the air capture machine to start the process over again.

Swiss company Climeworks is also quickly developing similar technology, having recently announced that it’s readying its first commercial-scale plant to extract carbon dioxide from the air and use it for a variety of purposes, including fuel manufacture.

Although it’s technically quicker to extract CO2 from the exhausts and chimneys of plants which burn fossil fuels to make electricity, Climeworks says that sourcing it from the air is much easier in the long run.

Dominique Kronenberg, Climeworks’ chief operating officer, said: “We don't have to purify exhaust gases from a boiler or coal - these have a lot of sulphur and other molecules that might be difficult to purify out.”

So could e-diesel ever really compete with established fossil fuels when it comes to price at the pump? The companies seem positive, at the least.

According to Sunfire’s estimates, its e-diesel will sell for between 73p to 100p per litre, slightly cheaper than the currently UK diesel price of 119p per litre.

However, a lot depends on how the government decides to tax the fuel. The actual price of the liquid fuel is as low as 30 per cent of what drivers actually pay at the pump, with the rest consisting of VAT, fuel duty and retailers’ profit.

In the US and in the UK, there are government initiatives to reduce greenhouse gas emissions via cleaner fuels, leading Mr Kronenberg to believe they might escape the same taxation as regular fuels. “We assume certain taxes might not be applied to these renewable fuels we produce,” he said.

That said, it’s the cost of electricity rather than the fuel itself that could make or break the viability of e-diesel, due to the fact that the conversion process typically takes large amounts of energy.

Dr Paul Fennell, of Imperial College London, said: “You can take electricity and convert it to fuel for your vehicle with about 13% efficiency. If you compare that to taking electricity and charging up an electric vehicle, then that can be done with about 80% efficiency.”

However, Adrian Corless, chief executive of Carbon Engineering, pointed out: “In the last two or three years, the cost of renewable electricity has dropped dramatically - especially solar.”

Yet another point in the favour of e-diesel is that the hundreds of millions of diesel vehicles already on the road, so cleaner fuel could at the least help the transition between regular fuels and zero carbon transport.

Both Climeworks and Carbon Engineering have also said that they use modular technology that makes it easy for them to scale up their processes to much larger projects.

As development continues, machines that create huge amounts of fuel simply from the air around them could become commonplace, and the US Navy has already expressed interest in using e-diesel for its ships.

As a result, it seems as though vehicles powered by fuel made from nothing but the air around them could be coming sooner rather than later. Still no word on those money trees, though.