Sorry to say it if you’re a long-term fan of Bernie Ecclestone’s circus, but it’s hard not to concede that with every season Formula One seems to be becoming more and more boring.

Stepping in to fill the gap has been all manner of new and exciting high-octane sports, ranging from rallycross to drift competitions and even low-budget banger racing as an antidote to the big budget spectacle of F1.

Of all of the up and coming new sports, however, potentially the most exciting is Formula E. It mightn’t be anywhere near as well-known or as watched as Formula One (yet), but it’s well on its way to becoming a real attraction.

While F1 headlines are choked up with driver versus driver speculation, Formula E concentrates on the thing that matters more than any petty rivalries: the cars. More about strategy than anything, from the limited energy available to the controversial car swap, Formula E is adding a new dimension to motor racing and gaining more fans by the day.

Though they might appear similar to F1 cars on the surface, strip away the body panels and underneath the cars are in fact full of some of the most exciting new technologies in motorsports today. Here’s how they work.

Exterior and chassis design

Like Formula One cars, the vehicles used in Formula E are optimised for aerodynamic efficiency, meaning that the cars can reach top speed more quickly, corner more effectively and overtake better than regular vehicles.

Although some parts of the car’s design is standardised, like the carbon/aluminium honeycomb survival cell manufactured by Italian chassis designer Dallara Automobili, teams are given free rein to choose other components, like brakes and suspension.

Generally, Formula E cars have a slightly higher ride height that F1 cars with a wide range of suspension set-up possibilities, as currently Formula E races take place on city centre streets and not dedicated race tracks.

As standard most cars feature double steel wishbone suspension with twin dampers, plus adjustable anti-roll bars for the front and rear. Two separate hydraulically-operated braking systems operated by the same pedal also come as a requirement, though teams are free to choose the brake material.

Battery

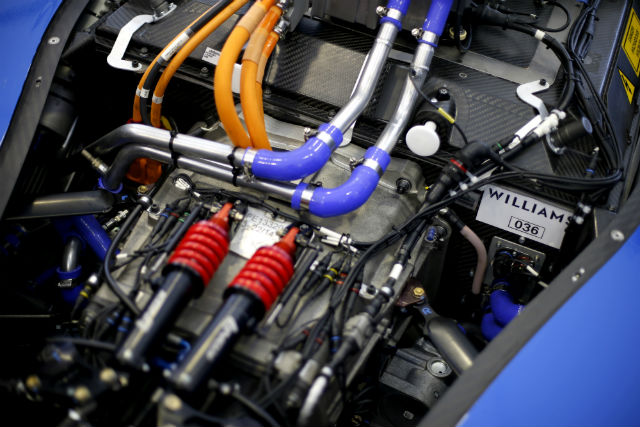

In principle, the battery is a store for energy, which makes it roughly analogous to the fuel tank in a regular combustion-engined car. All teams are required to use as standard a battery developed by Williams Advanced Engineering, which is made up of 200kg of lithium ion cells.

Approximately, each Formula E car’s battery has the same charge capacity as 300 laptops or 4,000 mobile phone batteries, but the maximum amount of energy all teams are allowed to use is 28kWh, which is represented on the TV graphics as a battery percentage.

In effect, this is the amount of ‘fuel’ that the car can carry, with all teams subject to the same standardised amount. Each car is also restricted in how much power it can put to the ground at any given time. During qualifying laps and with Formula E’s unique ‘fan boost’ maximum power peaks at 200kw, while the actual race itself restricts each car to a 150kw output.

The duration of the batteries depend heavily on how hard the driver pushes the car throughout the race, but each usually lasts between 25 and 30 minutes. Drivers are required to make a mandatory pit stop during the race in order to change their car for a fresh, fully-charged one.

Although the FIA admits that in a perfect world the series would use just one car, given the limits of current battery technology a one-hour race at full speed can’t be completed without recharging. Due to safety restrictions, teams can’t simply swap the battery in their car for a new one as each battery is sealed and not easily removed.

Motor and drivetrain components

While the batteries and maximum power available are strictly regulated, teams are free to fit their own motors, transmissions and inverters to distribute all that power and electrical energy to the car’s wheels.

The inverter contains a series of extremely high powered switches that can turn the power going to the motor on and off as many as tens of thousands of times per second. Essentially, the inverter manages the current sent to the motor, which in turn produces the power and torque that drives the car.

Interestingly, even road-going electric cars like the Nissan LEAF family hatchback need to be specifically mapped by engineers so that they don’t send 100 per cent of their power and torque to the wheels immediately. Unlike a combustion engine, which has a power curve, electric motors can send all of the car’s power to the ground instantaneously, which would cause the wheels to spin out and the car to go nowhere.

There are a number of different electric motors currently in use, but all of them operate based on the same basic design and each motor is made up of two main parts: the rotor which rotates and drives the driveshaft and the stator which encompasses the rotor and stay stationary.

Inside the motor assembly, the rotor carries extremely strong magnets, while the stator is covered in numerous coils of copper wire. Current from the battery is passed through the inverter and sent to the motor, where it creates a magnetic field upon passing through the stator’s coils.

Essentially acting like a giant electromagnet, the rotor’s magnets are attracted and repelled by the magnetic field generated by the stator, which causes the rotor to spin inside the motor’s housing.

It’s this which generates the Formula E car’s power, and the motor can spin at speeds of up to 20,000rpm, compared with the typical 18,000rpm limits of Formula One cars. The sheer power generated needs to be controlled via gears, with the size, maximum motor speed and the number of motors in the car ultimately determining how many gears the transmission needs.

How fast can a Formula E car go?

With all that power, it’s safe to say that Formula E cars are very, very fast indeed. Formula E rules state that they can run at an FIA-limited maximum speed of 140mph, while the cars can reach 0-62mph in around 2.8 seconds or so. It’s not quite Formula One fast, but it’s not slow either, with performance roughly comparable with top-tier road cars like the Nissan GT-R.

Despite the car’s extreme speed, one of the most unique aspects of Formula E cars is their sound on the track. Described by the FIA as “modern” and “futuristic”, the sound of the cars is a combination of tyre noise, the car’s aerodynamic package and the whirr of the electric drivetrain itself.

At top speed, each car reaches a top volume of around 80 decibels, compared to a traditional road car which produces around 70 decibels while travelling at 70mph. Traditional Formula One cars, meanwhile, are routinely so loud that spectators are advised to wear earplugs to protect their hearing when close to the track.

Real-world applications

Over the years, many developments for road-going cars have trickled down directly from Formula One. Whether it’s the road cars developed off the back of F1 success as per Ferrari’s modus operandi or the introduction of technologies like lightweight carbon fibre architecture, you can be sure that motorsports will continue to breed new and exciting tech for everyday cars.

However, while many top-line racing series make use of technological innovations developed specifically for the track, Formula E aims to be directly relevant to road cars.

Particularly in terms of developing electric vehicles, understanding how to wring the best possible performance from electric race cars can and will help everyday drivers better understand and use electric and hybrid vehicles.