The internal combustion engine is an aging, archaic piece of technology and will soon be replaced by electric motors, at least according to the proponents of electric power.

When you think about it, it’s easy to see why. Every single car on the road with an engine is powered by the same technology developed by Dutch physicist Christian Huygens all the way back in 1680 - 336 years ago.

Sure, today’s engines are a lot more refined. They still use the same basic mechanism of exploding fossil fuels under pressure to create motion, but these days they make much more power with far fewer harmful emissions.

Yet ever-tightening pollution standards across the globe will mean that the car as we know it will one day become a thing of the past, won’t it? Perhaps not.

Engineers around the world are constantly working to increasingly improve and revolutionise the combustion engine, and here are three of the most innovative and exciting developments that could mean the engine continues to endure, perhaps even for the next 336 years.

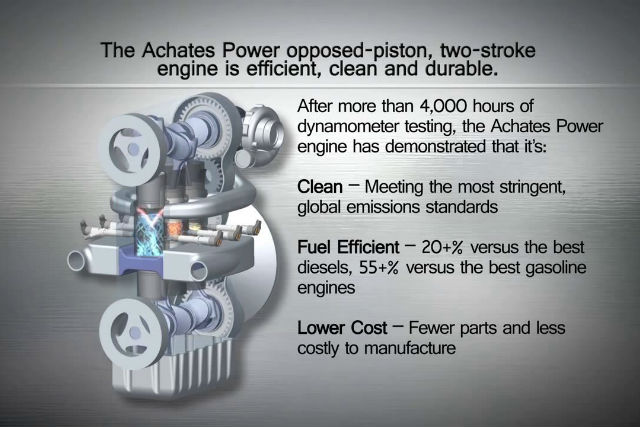

Achates Power Opposed-Piston Engine

What is it?

Achates Power has the most revolutionary approach to improving the combustion engine, and believes that all current designs should be replaced by an idea abandoned in the 1940s: opposing piston technology.

The vast majority of combustion engines on sale today use cylinders with a single piston inside to draw in air and fuel, and then compress it. This squishes the mixture, while a spark creates an explosion that drives the piston down, thereby generating power.

However, Achates wants to chuck that out in favour of a design which uses two pistons in each cylinder, instead of only one.

What does it do?

Simply put, the two pistons oppose each other inside the cylinder and the fuel/air mixture is injected between the two. When the mixture ignites, it pushes both pistons apart to generate power.

Engines of this design are much simpler and don’t use traditional valves or camshafts, and many trains and military vehicles used to use this type of engine until engineers abandoned them due to the fact they couldn’t make them run efficiently enough – a problem with Achates Power says it’s now fixed.

What does that mean?

Due to the fact that each explosion drives two pistons instead of one, the Achates engine uses two crankshafts instead of just one, so essentially you get twice the power for the same amount of fuel burnt as a traditional engine.

That makes this engine much more fuel efficient than a regular engine, and Achates says its design is as much as 55 per cent more efficient than the best petrol engines currently on sale. Its much simpler design means that it’s less expensive to make, less expensive to buy and simpler to repair.

Finally, engines of this type are typically a lot more compact than traditional engines, which will reduce weight and thereby also increase the efficiency of vehicles and also free up a lot more room on the inside for passengers.

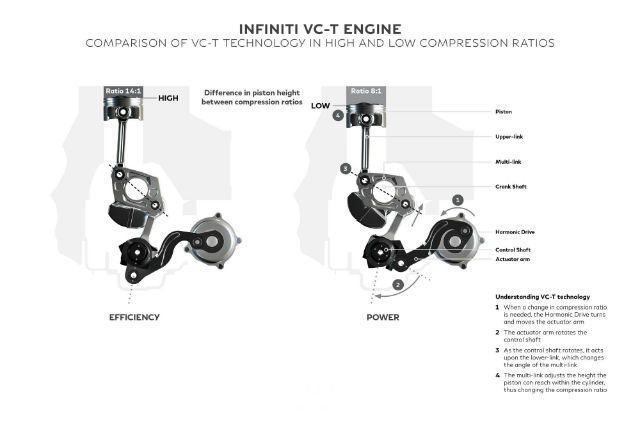

Nissan Infiniti VC-T Engine

What is it?

To improve emissions and get more power from less fuel, there are a couple of things you can do. First, you can reduce the size of the engine so you’re burning through less petrol per cycle, you can add a turbocharger to get more power from the fuel you use or vary the valve timing to add more or less air to the mixture, thereby controlling how clean the explosions burn.

Now, Nissan says it’s developed another tool to add to the kit: the ability to vary an engine’s compression ratio with its new Variable Compression Turbocharged (VC-T) engine.

What does it do?

The amount of compression - how hard the piston squeezes the fuel/air mixture inside the cylinder - always tends to be something of a compromise. Compressing the mixture under high pressure maximises performance but can cause the fuel to prematurely ignite, thereby degrading performance, increasing emissions and potentially damaging the engine.

Most manufacturers therefore pick a compression ratio somewhere in the middle to compromise economy and performance, but the problem is that once it’s set it can’t be changed. Nissan’s VC-T engine features an adjustable arm, which alters how much the piston can compress the fuel/air mixture.

It’s a fairly complex system, but it allows the engine to operate at compression ratios anywhere between 8:1 - a fairly low compression ratio - to 14:1, which is higher than many supercars.

What does that mean?

Essentially, it means an end to the compromises that engineers have had to settle for since the combustion engine was invented. When cruising, the engine can use high compression to get as much bang as possible from each drop of fuel, thereby decreasing emissions.

Then, when the engine is under high stress, the car’s computer systems can automatically reduce the compression ratio to avoid premature ignition.

Nissan says a four-cylinder engine equipped with the VC-T technology can achieve the same power and torque as a much larger V6, while also delivering fuel economy increases of 27 per cent or more.

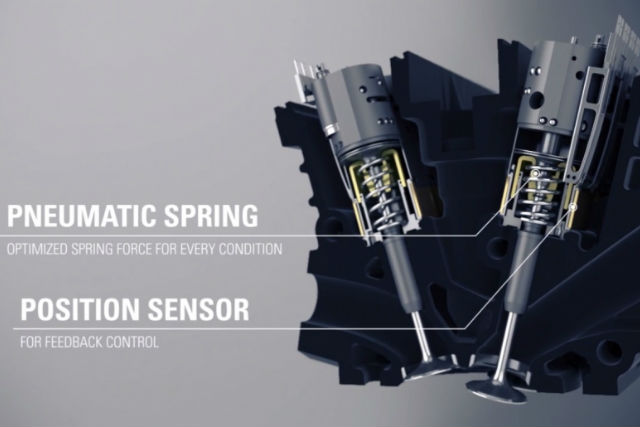

Koenigsegg FreeValve

What is it?

FreeValve is the latest, and arguably the greatest, achievement to date from Christian von Koenigsegg, the unbelievably brilliant inventor behind Swedish supercar skunkworks company Koenigsegg.

Conventional engines use valves to let air into the engine cylinders and then release the exhaust when the fuel/air mixture has combusted. How long the valves stay open and how fast they move are of vital importance to how an engine operates, and this valve timing is controlled by a cylindrical metal bar called a camshaft.

Camshafts are fitted with egg-shaped lobes to close the valves, which then spring back open the lobes roll off them. However, Koenigsegg’s FreeValve technology ditches the idea of a camshaft completely and allows each valve to operate independently.

What does it do?

FreeValve uses a pneumatic system to open and close the valves, which can be controlled by the car’s computer systems. It allows each valve to open and shut instantaneously, and can even prevent the valves from opening at all – essentially shutting down that part of the engine.

FreeValve is currently one of the most exciting technologies anywhere in the automotive industry, due to the fact that the sheer possibilities independently-controller valves open up are nearly limitless.

What does that mean?

The headline figures which Koenigsegg claims is a 47 per cent increase in torque, 30 per cent more horsepower, 30 per cent less fuel consumption and a massive 50 per cent fewer emissions.

With camshafts and therefore timing belts out the window it also means much smaller engines and better packaging, plus potentially reduced maintenance costs, though manufacturing costs will likely be high.

As well as that, the fact that each valve can be electronically controlled allows for infinite tuning capabilities. Imagine a three-cylinder engine with the power of a V8 but a third of the weight. Or a car which can shut all but one of its cylinders down when driving in town to dramatically reduce fuel consumption.

Potentially, FreeValve would also allow people to customise the way their engines perform and behave. You could have a V8 programmed to mimic the loping idle of a Ford Mustang and then, at the push of a button, transform it into a high-revving Formula One-style engine.